Customized Product Solutions

Industry Focused Expertise

Technical Know-How

Service & Support since 1954

We make our customers successful by offering:

Technical Expertise and Product & Application Support

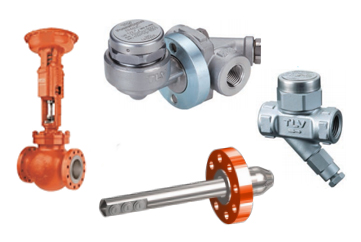

With a team of in-house engineers, along with instrumentation and valve customization services, we can design and customize product solutions to help you solve complex problems and upgrade your facilities for the future. Our engineers design tailor-made solutions to help customers solve their difficult process-control problems from concept to providing technical support, long after the initial sale.

Ease of Doing Business

& Customer

Peace of Mind

We partner with the world’s most respected and well-known brands. Additionally, we have dedicated quote and order teams who respond to all customer inquiries and quotes as fast and efficiently as possible. The team provides ease of ordering by delivering fast customer attention, swift action, and access to product and application knowledge to ensure the best product offering specific to your individual needs.

In-House Valve Automation

Through our valve automation capabilities, Rawson & Industrial Controls customers receive a complete valve package – control or shutoff valve, actuator, and valve accessories – that is assembled, tested, and ready for installation, along with complete documentation of engineering drawings for assemblies in both standard and custom valve configurations.